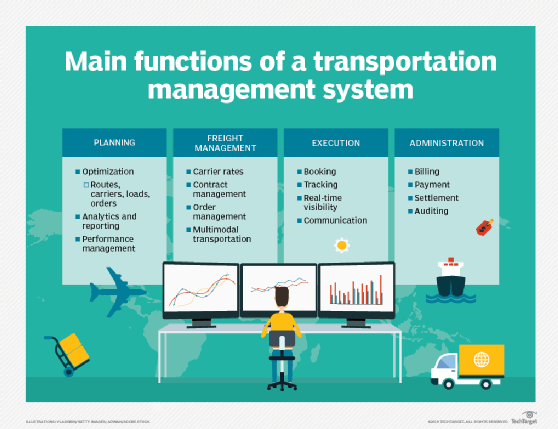

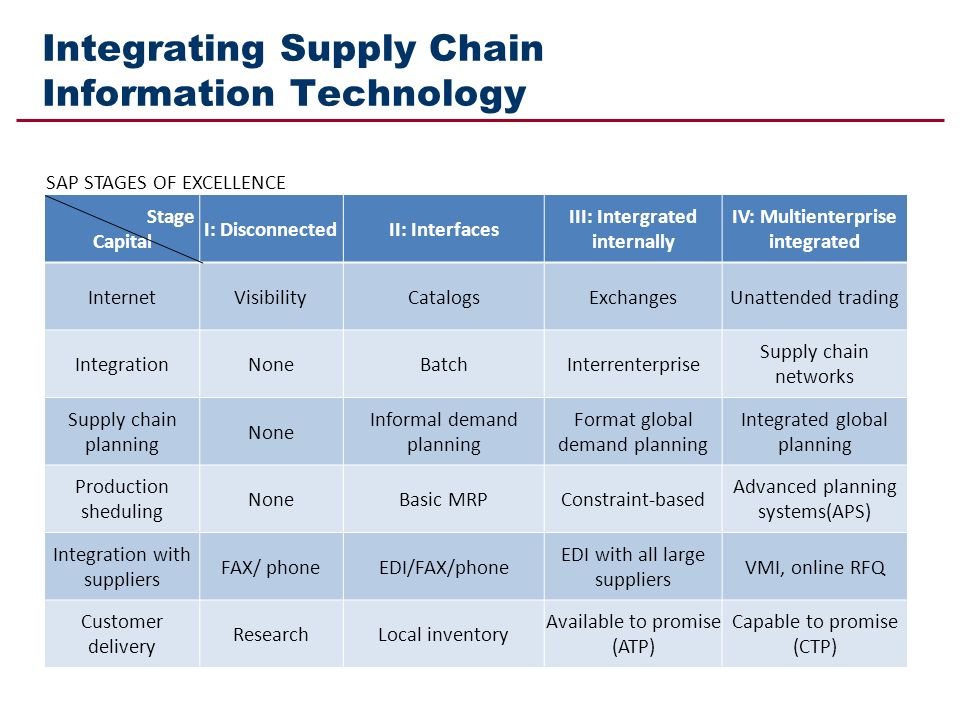

Supply chain planning scp and supply chain execution are the two main categories of scm software.

Supply chain planning systems track the physical status of goods.

Supply chain planning systems perform all of the following functions except a establish inventory levels for raw materials and finished goods.

B identify the transportation mode to use for product delivery.

Supply chain planning systems a track the physical status of goods.

Suppliers who supply the primary with the goods to make the finished product.

Track the financial information involving all parties.

D track the status of orders.

Supply chain execution systems track physical status of goods.

The system takes its name from the cards that track production within a factory.

Supply chain planning systems a track the physical status of goods.

C track the financial information involving all parties.

With sap global track and trace you can get real time insights into the availability of materials and products to reduce supply chain risks and optimize costs.

Track the status of orders.

Determine how much product to manufacture in a given time period.

Supply chain planning systems track the physical status of goods.

A track the physical status of goods b identify the transportation mode to use for the product delivery c track the financial info involving all parties d track the status of orders.

Scp software applications apply algorithms to predict future requirements and balance supply and demand.

E track the management of materials.

B identify the transportation mode to use for product delivery.

Supply chain planning systems.

E track the physical status of goods.

Supply chain planning systems.

D track the status of orders.

Sce software applications track the physical status of goods the management of materials and financial information involving all parties.

Enable the firm to model its existing supply chain generate demand forecasts for products and develop optimal sourcing and manufacturing plans.

Identify the transportation mode to use for product delivery.

C track the financial information involving all parties.

A track the physical status of goods.

Taiichi ohno an industrial engineer at toyota developed kanban to improve manufacturing efficiency kanban is one method to achieve jit.

D track the status of orders.

Deliver on your promise to customers by tracking the status and fulfillment of processes and goods in transit across your global inbound manufacturing and fulfillment chain.

Kanban 看板 signboard or billboard in japanese is a scheduling system for lean manufacturing and just in time manufacturing jit.

Supply chain planning systems.

B identify the transportation mode to use for the product delivery.

D managing warehouse.

C track the financial information involving all parties.